Happy New Year

Populære søgeord

Bagmekanik

Loddepasta

Champagne diamant

Diamond

Diamonds are one of the most coveted and prestigious of all the gemstones. There are several factors that influence the quality of a diamond. To classify this value, one should take a closer look at the four Cs:

1. Carat 2. Color 3. Clarity 4. Cut

1. CARAT

The carat or weight is the easiest to determine, simply by weighing the stone. 1 ct. diamond equals 0.2 grams. Large diamond crystals are far more rare than small ones. The price level for large cut diamonds is therefore significantly higher and sharply increases in size. For example, a diamond costs 1ct. more than double a diamond of ½ ct. of similar quality.

|

C mm |

1,30 |

1,70 |

2,50 |

2,70 |

3,10 |

3,30 |

3,50 |

3,70 |

3,80 |

3,95 |

4,10 |

4,60 |

5,00 |

5,80 |

6,20 |

7,00 |

8,80 |

11,10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Carat |

0,010 |

0,020 |

0,060 |

0,080 |

0,120 |

0,140 |

0,160 |

0,180 |

0,200 |

0,230 |

0,250 |

0,350 |

0,450 |

0,650 |

0,850 |

1,250 |

2,500 |

5,000 |

| Brillant |  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. Color

Diamonds with intense color are very rare and expensive. They are called colored diamonds or fantasy diamonds. The fantasy diamond includes e.g. The Hope Diamond and The Dresden Green. Many diamonds have a faint yellowish color. However, the hues are so faint that only a trained eye is able to distinguish them. The very small shades of white to yellowish can not be described using common color designations. See the overview below, which contains both the Danish names and the American degrees from GIA (Gemmological Institute of America).

The color designation is necessary in order to provide the correct commercial descriptions. The colors do not constitute whether a diamond is good or bad; terms like rare and less rare is better suited.

3. Clarity

The transparency of diamonds varies greatly from stone to stone. Often, inclusions, e.g. foreign bodies, crevices or surface scratches, to some extent the free passage of light, reduce transparency. When the inclusions reduce the transparency so much that it appears completely opaque, it is sold to industry as industrial diamonds. Only very few diamonds are completely clear - and as a result very expensive. Even very small inclusions that do not visibly reduce transparency and therefore do not affect the beauty of the diamond are the cause of depreciation. Only when the inclusions are of such a size that they can be seen with the naked eye, is there a deterioration in the beauty of the stone. The purity of the diamond is determined with a magnifying glass with a maximum of 10 times magnification - and purity grading should only be done on unframed stones.

The Scandinavian Diamond Nomenclature (later Scan. D.N.) purity scale - seen below - is divided into main and sub-degrees. The highest step on the scale is Lup-ren with the subgrades FL (flawless) and IF (internally flawless). The FL degree indicates that the diamond below 10 times magnification does not show internal or external impurities. The IF degree allows quite small external errors, but no internal ones.

The terms VVS, VS and SI are formed from the terms very very small inclusions, very small inclusions and small inclusions.

Only in the last step, the P-degrees, also called Piqué, are the inclusions so large that they can be seen with the naked eye.

|

Main-degree |

Lup-ren | VVS | VS | P | |||||

|---|---|---|---|---|---|---|---|---|---|

|

Sub-degree |

FL | IF | VVS 1 | VVS 2 | VS 1 | VS 2 | P 1 | P 2 | P3 |

4. Cut

The three previous factors - carat, color and clarity - are all natural and are described as rarity factors. The fourth - cut - is performed by humans, and can rightly be called a quality factor.

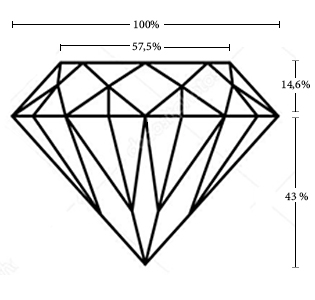

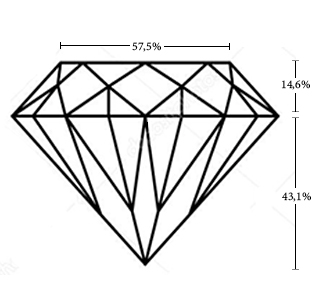

The diamond's unique optical property is only fully unfolded through the cut. The correctly proportioned brilliant-cut manages to highlight the light effects to a greater extent than other sharpening forms: brilliance, fire, gloss and glitter, in a beautiful combination. The illustration above shows Scan. D.N. 's cut, where the height of the upper part is 14.6%, the depth of the lower part 43.1% and the board diameter 57.5% of the diameter of the round member. These proportions are carefully calculated, and even small deviations from this will most often impair the light effect of the stone. In the illustrations below, the lower part is too flat (b) and too deep (c), which reduces the light effect in relation to the correct proportioned cut (a).

| (a) | (b) | (c) |

|---|---|---|

|

|

|

|

|

|

|

The light effect from a correctly proportioned brilliant. |

Brilliant with a too flat bottom. The stone loses much of its light effect in the middle because only a small part of the light is reflected. It is often referred to as a fish eye. |

Brilliant with a too deep bottom. The stone appears dark in the middle - because the light disappears from the lower part. It is often referred to as lumpy stone. |

As previously mentioned, the proportions of the brilliant cut are decisive for how brilliant and how strong the fire can be achieved in the brilliant. The Scan. D. N. cut is calculated based on a desire to achieve the optimal combination of brilliance and fire as the most important thing. However, it is not clear what the optimal lighting effect is. Some will think that the brilliance is the most important light effect, others will think that the fire of the brilliant is the most important. Due to the laws of nature (total reflection and the critical angle), the diamond cut cannot simultaneously fulfill the wishes of both parties to an equal degree and one must therefore prioritize. In the past, by experimentally changing the inclination of the facets and their mutual size ratio, the diamond cutter has been able to experiment with brilliants with increasingly greater light effect. In this way, many of the diamond grinders of the time achieved results that are close to today's cutting methods. Later, the light effect in the brilliant has been studied theoretically. In 1919, the English mathematician Marcel Tolkowsky presented the result of his scientific calculations on the ideal cut, the so-called Tolkowksy diamond.

| Tolkowsky-brillant | The Scandinavian Diamond Nomenclature |

|

|

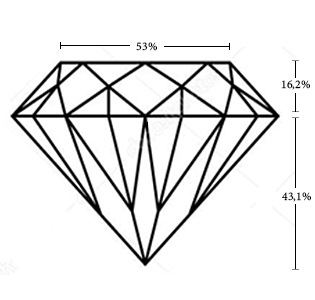

As shown on the Scan. D.N. it is always based on the diameter of the disc, which is set to 100, the other dimensions appear as a % of this. The difference between the two cuts is, as can be seen from the drawing, limited to the upper part of the brilliant. The facet of the Tolkowsky brilliant is 53% and the height of the top is 16.2%, which means that this cut produces a slightly stronger fire at the expense of the brilliance. The Scan D.N. cut, which as you know has a slate facet of 57.5% and an upper part height of 14.6% gives a slightly stronger brilliance at the expense of the stone's fire. It can be added that the stones are viewed from above, the Scan D.N. is slightly larger than the Tolkowsky diamond, even though they have the same round diamond diameter. The reason is probably found in the size of the board facet.

Cutting failures

Larger deviations from the standard cut are usually not due to a bad diamond sharpener, but must be attributed to the high value of the raw material. The rough diamond crystals are very different. The shape of the crystals and the location of any impurities are factors that the diamond grinder must take into account. In principle, one could cut a properly proportioned diamond from any crystal simply by making the stone sufficiently small. But such an approach will cause such a great waste of the precious diamond material that the price per ct. would be unreasonably high. In addition, you must expect to lose min. 60% of the raw material's weight during cutting, so the diamond cut must therefore deviate to a greater or lesser extent from the ideal.

Facet

The brilliant cut has 57 or 58 facets distributed as follows:

The upper part

- 1 board facet

- 8 star facets

- 8 main facets

- 16 rondist facets

A total of 33

The lower part

- 8 main facets

- 16 rondist facets

A total of 24 or 25 if the culet is ground

Culet

The facets of the lower part can end in a point or in a small 8-sided surface. If the facets meet at a point, we speak of a pointed culet. If the cut ends with a flat surface, it is called a sanded culet. Diamonds are usually cut with a pointed culet. However, you must also be prepared for a bumpy culet, where the culet appears uneven.

Other cuts

| Pearshape | Oval | Navette/Marquise | Heart |

|---|---|---|---|

|

|

|

|

| Square/carre | Princess | Triangle | Trilliant |

|

|

|

|

| Baguette | Emerald | ||

|

|

||

Polycrystalline Diamonds

Polycrystalline Diamond (PCD) is diamond powder that has been fused together under high-pressure, high-temperature conditions in the presence of a catalytic metal. Typically PCD is bonded to a tingsten/wolfram carbid substrate under high temperature and high pressure (HTHP). This sintered diamond and tungsten carbide is known as the polycrystalline diamond

Hardness

Diamonds are the hardest material known, harder than tungsten carbide, steel, silicon nitride and silicon carbide. It is therefore ideal for use that requires greater toughness and durability. Sintered diamond-to-diamond particles in a coherent structure through HPHT. Randomly oriented diamond-to-diamond bonds ensure that there are no soft fracture surfaces, combined with the extreme hardness, wear resistance, and thermal conductivity of diamonds make it an ideal material for the cutting tools manufacturing.

DURABILITY

- Combines toughness and hardness for improved durability

- Handles extremely high loads

- Has lower friction resistance than tungsten carbide, steel and Teflon

- Resistant to all acids and bases

- Withstands high temperatures

- Higher fracture toughness than silicon nitride and silicon carbide

Thermal conductivity

- Highest thermal conductivity available in an engineering material

- Reduces local external temperatures that lead to significant deterioration

- Distributes heat better than tungsten carbide, steel silicon nitride, silicon carbide and even copper

- Excellent for hob and applications in harsh environments

Special Care Instructions

Color Enhanced Diamonds like natural color diamonds are not subject to change over time. Special care is only required if the diamonds are exposed to extreme heat over 950 degrees F/500 degrees Celsius.

Jewelers should treat the diamonds the same way as they treat the gemstone ‘Emerald’. Jewelers can use ‘Heat Shield’ to protect the diamond during resizing the ring or any process that requires extreme heat.

In addition to the above, Black Diamonds should not be exposed to rhodium, ultrasonic or any other kind of acid.

Contact

Frits Pedersen

Haraldshus,

vermundsgade 38B, st. th.

2100 København Ø

Phone +45 35 43 11 11

Fax +45 25 43 33 44

E-mail fp@frits.dk

Opening hours

Monday-Thursday 8:00-16:00

Friday 8:00-15:00